Author: Jürgen Fischer Position: Product Manager Linear Motion Technology, Bosch Rexroth AG

Whether it be consumer goods, medical technology or 3D printing: Countless small parts need to be moved precisely and cost-effectively. This is now much easier.

When you hear “SMS”, you don’t immediately think of linear modules. But you should remember the term in this context as well. After all, these three letters refer to a cutting-edge, particularly cost-effective solution for handling the small parts found in a wide range of sectors. They include the consumer goods and packaging industry, semiconductor and battery production, 3D printing, the automotive sector, medical technology and mechanical engineering.

Exact positioning, compact and low maintenance requirements

Many of these applications require a high repeatability of up to ± 0.005 mm with low to medium dynamics. And if the design is compact, robust and requires little maintenance – all the better! The new SMS linear modules from Bosch Rexroth meet exactly these requirements and help to reduce system and life cycle costs. They also welcome an alternative to pneumatically driven axes and provide a good opportunity for electrification with all of the associated benefits.

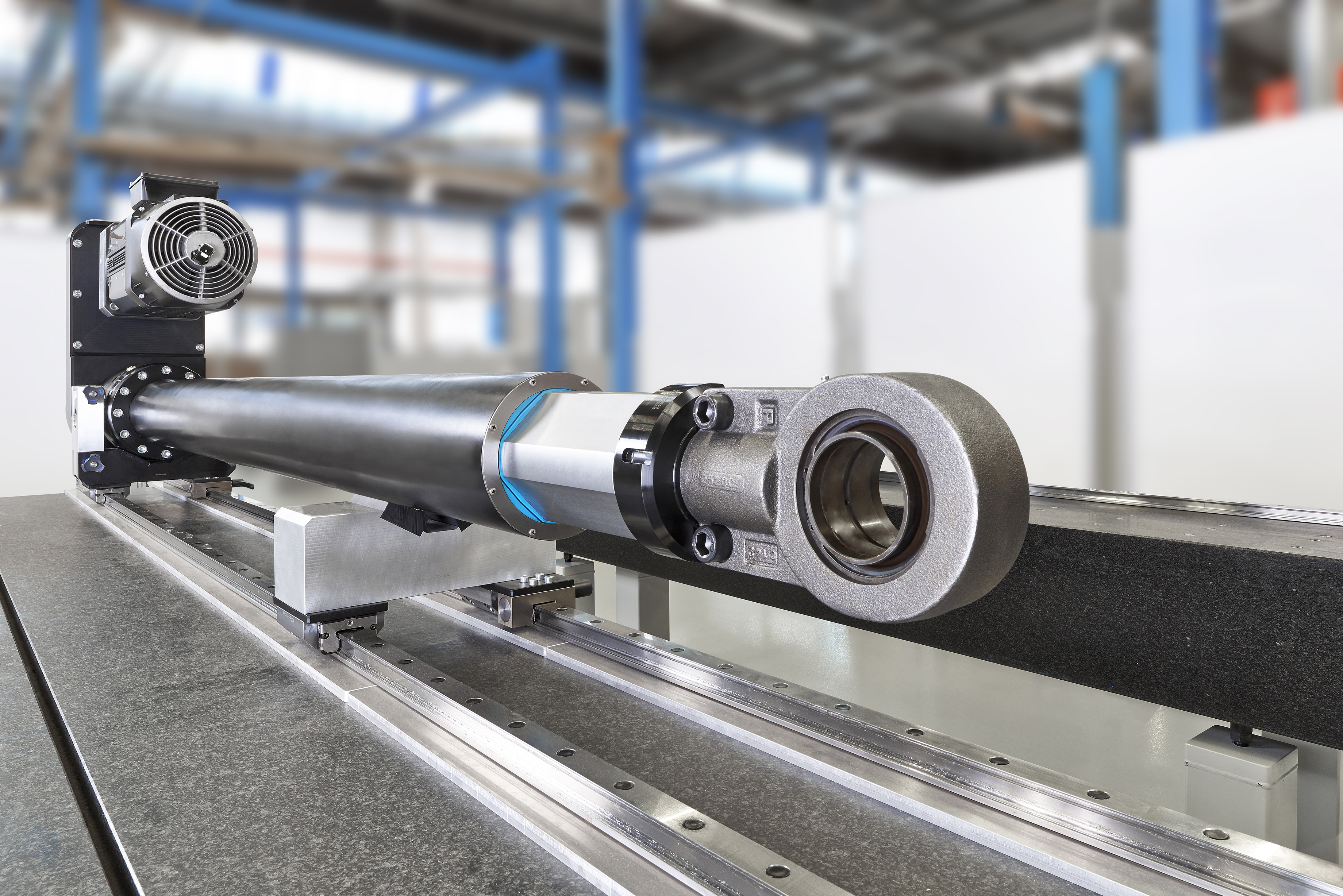

Robust linear modules with ball screw assembly

The compact SMS modules with ball screw assembly (Small Modules Screw driven) are manufactured to the usual Rexroth quality standards and impress with their flat aluminum profile offering integrated, precise guidance. In addition, a magnetically fixed steel cover strip protects the components inside.

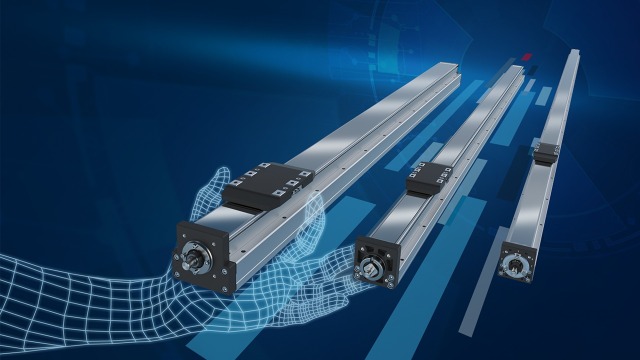

Quick selection, available from stock

To ensure the shortest possible delivery times, the SMS linear modules can be ordered from stock. The five tailored sizes range from 30 to 120 mm and are suitable for travel ranges of up to 1,200 mm. They can be selected and ordered easily from the Rexroth online shop with the help of a product selector. Optional attachment sets for popular servo motors are available – either as a belt side drive or a flange coupling. Naturally, a choice of motors and drive controllers from Bosch Rexroth is available too.

Conclusion: Expanded portfolio saves time and money

The SMS linear modules expand the range of linear axes, adding an ultra-compact series with a particularly flat design offering excellent value for money. Simple positioning and delivery tasks can thus be carried out economically – and at short notice. This opens up an attractive electrification path for greater precision, flexibility and energy efficiency in production – two key qualities in the Factory of the Future.

CMA/Flodyne/Hydradyne is an authorized Bosch Rexroth distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.