Guest Contributor: Tom Knauer, Balluff

Manufacturing is rapidly changing, driven by trends such as low volume/high mix, shorter life cycles, changing labor dynamics and other global factors. One way industry is responding to these trends is by changing the way humans and machines safely work together, enabled by updated standards and new technologies including safety communications.

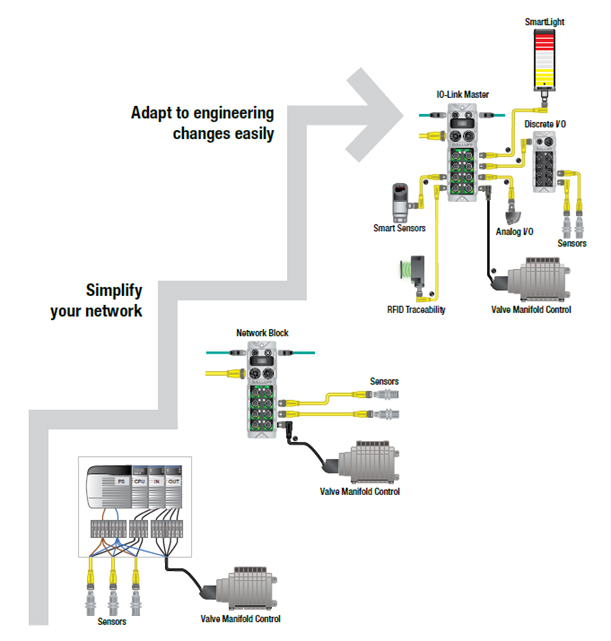

In the past, safety systems utilized hard-wired connections, often resulting in long cable runs, large wire bundles, difficult troubleshooting and inflexible designs. The more recent shift to safety networks addresses these issues and allows fast, secure and reliable communications between the various components in a safety control system. Another benefit of these communications systems is that they are key elements in implementing the Industrial Internet of Things (IIoT) and Industry 4.0 solutions.

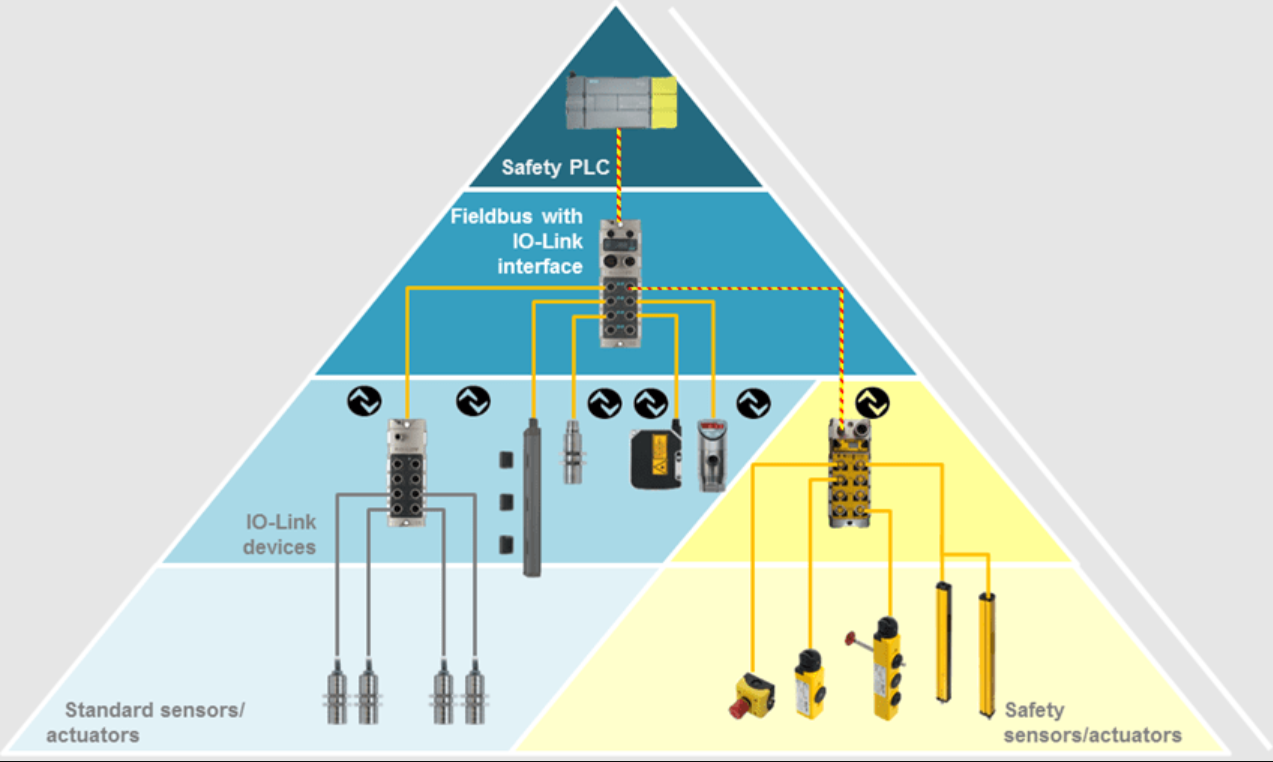

Within a typical factory, there are three or more communications levels, including an Enterprise level (Ethernet), a Control level (Ethernet based industrial protocol) and a Device/sensor level (various technologies). The popularity of control and device level industrial communications for standard control systems has led to strong demand for similar safety communications solutions.

Safety architectures based on the most popular control level protocols are now common and often reside on the same physical media, thereby simplifying wiring and control schemes. The table, below, includes a list of the most common safety control level protocols with their Ethernet-based industrial “parent” protocols and the governing organizations:

| Ethernet Based Safety Protocol |

Ethernet Based Control Protocol |

Governing Organization |

| CIP Safety |

Ethernet IP |

Open DeviceNet Vendor Association (ODVA) |

| PROFISafe |

PROFINET |

PROFIBUS and PROFINET International (PI) |

| Fail Safe over EtherCAT (FSoE) |

EtherCAT |

EtherCAT Technology Group |

| CC-Link IE Safety |

CC-Link IE |

CC-Link Partner Association |

| openSAFETY |

Ethernet POWERLINK |

Ethernet POWERLINK Standardization Group (EPSG) |

These Ethernet-based safety protocols are high speed, can carry fairly large amounts of information and are excellent for exchanging data between higher level devices such as safety PLCs, drives, CNCs, HMIs, motion controllers, remote safety I/O and advanced safety devices. Ethernet is familiar to most customers, and these protocols are open and supported by many vendors and device suppliers – customers can create systems utilizing products from multiple suppliers. One drawback, however, is that devices compatible with one protocol are not compatible with other protocols, requiring vendors to offer multiple communication connection options for their devices. Other drawbacks include the high cost to connect, the need to use one IP address per connected device and strong influence by a single supplier over some protocols.

Device level safety protocols are fairly new and less common, and realize many of the same benefits as the Ethernet-based safety protocols while addressing some of the drawbacks. As with Ethernet protocols, a wide variety of safety devices can be connected (often from a range of suppliers), wiring and troubleshooting are simplified, and more data can be gathered than with hard wiring. The disadvantages are that they are usually slower, carry much less data and cover shorter distances than Ethernet protocols. On the other hand, device connections are physically smaller, much less expensive and do not use up IP addresses, allowing the integration into small, low cost devices including E-stops, safety switches, inductive safety sensors and simple safety light curtains.

| Device level Safety Protocol |

Device level Standard Protocol |

Open or Proprietary |

Governing Organization |

| Safety Over IO-Link/IO-Link Safety* |

IO-Link |

Semi-open/Open |

Balluff/IO-Link Consortium |

| AS-Interface Safety at Work (ASISafe) |

AS-Interface (AS-I) |

Open |

AS-International |

| Flexi Loop |

|

Proprietary |

Sick GmbH |

| GuardLink |

|

Proprietary |

Rockwell Automation |

* Safety Over IO-Link is the first implementation of safety and IO-Link. The specification for IO-Link Safety was released recently and devices are not yet available.

The awareness of, and the need for, device level safety communications will increase with the desire to more tightly integrate safety and standard sensors into control systems. This will be driven by the need to:

- Reduce and simplify wiring

- Add flexibility to scale up, down or change solutions

- Improve troubleshooting

- Mix of best-in-class components from a variety of suppliers to optimize solutions

- Gather and distribute IIoT data upwards to higher level systems

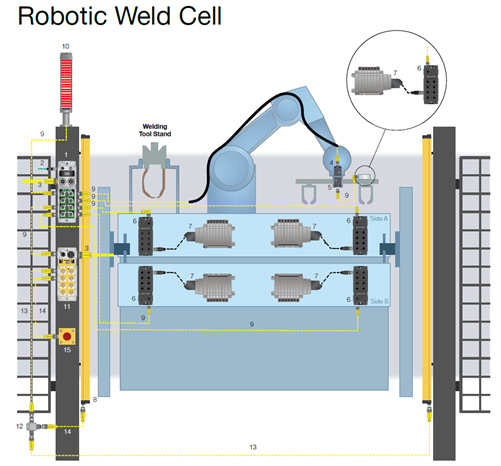

Many users are realizing that neither an Ethernet-based safety protocol, nor a device level safety protocol can meet all their needs, especially if they are trying to implement a cost-effective, comprehensive safety solution which can also support their IIoT needs. This is where a safety communications master (or bridge) comes in – it can connect a device level safety protocol to a control level safety protocol, allowing low cost sensor connection and data gathering at the device level, and transmission of this data to the higher-level communications and control system.

An example of this architecture is Safety Over IO-Link on PROFISafe/PROFINET. Devices such as safety light curtains, E-stops and safety switches are connected to a “Safety Hub” which has implemented the Safety Over IO-Link protocol. This hub communicates via a “black channel” over a PROFINET/IO-Link Master to a PROFISafe PLC. The safety device connections are very simple and inexpensive (off the shelf cables & standard M12 connectors), and the more expensive (and more capable) Ethernet (PROFINET/PROFISafe) connections are only made where they are needed: at the masters, PLCs and other control level devices. And an added benefit is that standard and safety sensors can both connect through the PROFINET/IO-Link Master, simplifying the device level architecture.

Combining device level and control level protocols helps users optimize their safety communications solutions, balancing cost, data and speed requirements, and allows IIoT data to be gathered and distributed upwards to control and MES systems.

CMA/Flodyne/Hydradyne is an authorized Balluff distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

CMA/Flodyne/Hydradyne is an authorized Balluff distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.

No drive technology is more efficient, compact and robust than hydraulics when dealing with forces in excess of 600 kN. So why is it that the importance of hydraulics is often overlooked in the training and development of our young engineers?

No drive technology is more efficient, compact and robust than hydraulics when dealing with forces in excess of 600 kN. So why is it that the importance of hydraulics is often overlooked in the training and development of our young engineers?

CMA/Flodyne/Hydradyne

CMA/Flodyne/Hydradyne