Steffen Winkler

Game Changer

ctrlX AUTOMATION

- ctrlX DRIVE cabinet-free reduces space and cabling by up to 90 percent

- Modular, flexible, and energy-efficient IP65 system

- Bosch Rexroth is a pioneer in cabinet-free drive technology

Modularity, simple installation, and drastically reduced space requirements as well as minimum cabling – these are the key benefits of cabinet-free drive technology. Based on 20 years of development experience in this field, Bosch Rexroth now also offers a cabinet-free solution in protection class IP65 with the ctrlX DRIVE cabinet-free. Bosch Rexroth sees these solutions as the future of servo drive technology, as they ideally meet the increasing requirements for efficiency and adaptability in modern production environments.

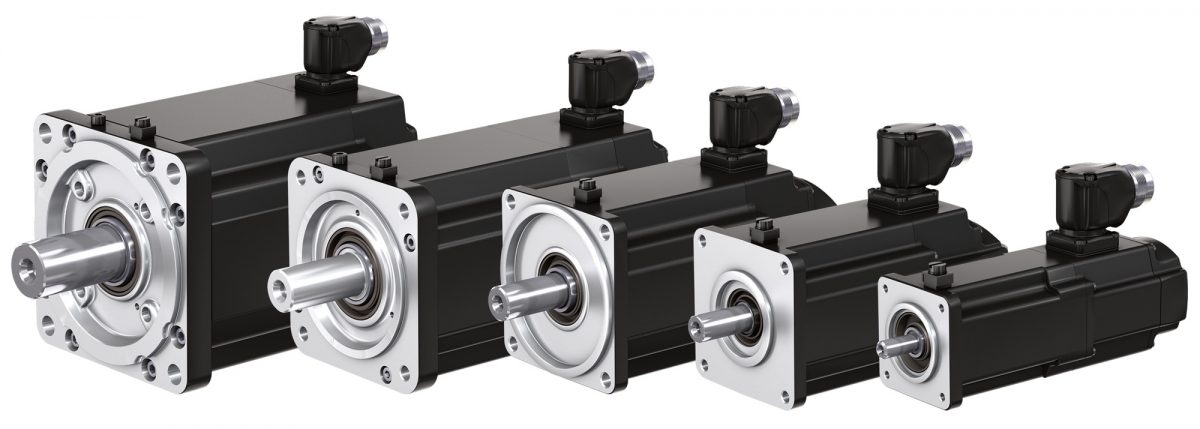

Modular, flexible and energy-efficient system: the new ctrlX DRIVE cabinet-free.

“Today, more than ever, mechanical engineering is about saving space, reducing costs, and enabling rapid adaptation to new challenges,” says Steffen Winkler, Senior Vice President Sales Business Unit Automation & Electrification Solutions at Bosch Rexroth.

Bosch Rexroth is a pioneer in cabinet-free drive technology. The company presented its first solutions some 20 years ago and has been implementing numerous projects worldwide ever since. With the new ctrlX DRIVE cabinet-free, Bosch Rexroth presents the next stage of development for this technology, which meets the requirements of modern machine designs.

The servo drive of the future is flexible and saves space and energy

Control cabinets take up space and are expensive to install and service. The ctrlX DRIVE cabinet-free IP65 system almost completely eliminates the control cabinet and reduces the space and cabling requirements by up to 90 percent. This not only saves time and costs, but also makes assembly, project planning, and operation easier.

Furthermore, the cabinet-free solution enables energy savings of up to 70 percent. The decentralized design eliminates energy consumption for control cabinet air-conditioning, which lowers operating costs. In addition, the ctrlX DRIVE cabinet-free uses silicon carbide semiconductors (SiC technology), which significantly reduce energy losses and thus increase overall energy efficiency.

ctrlX DRIVE cabinet-free offers maximum flexibility in application. Mechanical engineers can choose from an extensive product portfolio that includes single and dual-axis inverters with currents from 6 to 54 A. The drives are freely scalable – up to 100 drives can be operated in a line with a total length of up to 200 m. With multi-Ethernet interfaces, freely selectable motors, and modular expansion options, the system offers solutions for a wide range of industries and applications.

The machine can be adapted and expanded easily thanks to the system’s modular design. As a result, machines can be flexibly configured to meet new requirements without having to completely change existing structures.

“Cabinet-free drive technology already pays off during the machine development process. It speeds up time-to-market and project realization. And in practical applications, users benefit from greater flexibility and potential savings, for example in terms of energy. With ctrlX DRIVE cabinet-free, we are driving forward the development of innovative, future-oriented machines,” says Winkler.

To learn more, please visit www.boschrexroth.com

CMA/Flodyne/Hydradyne is an authorized Bosch Rexroth distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.

CMA/Flodyne/Hydradyne

CMA/Flodyne/Hydradyne