Guest contributor, Frank Kaufmann, Bosch Rexroth

However efficient PLC programming for complex tasks may be, it is often relatively time-consuming for simple and moderately complex automation solutions. In light of scarce internal resources, machine manufacturers are looking for ways to speed up engineering and shorten delivery times. A new solution is Sequential Motion Control SMC, a virtually universal technology function for IndraDrive servo drives. It reduces users’ programming and commissioning work by up to 90 percent compared to PLC programming.

Career portals clearly show the lack of skilled labor: in Germany alone, there are more than ten thousand vacancies for PLC programming and commissioning specialists. The situation is no better in other countries. The lack of skilled labor not only lengthens the time to market for new machines – it also makes it more difficult to develop lucrative services, for example adapting installed stations to new tasks.

If orders are delayed owing to capacity bottlenecks, this annoys customers. This makes it all the more important to come up with an alternative to complex, time-consuming PLC programming. This is where drive-based Sequential Motion Control SMC comes in. It uses the intelligence of servo drives for applications with up to six axes yet requires no external motion control system. The integrated motion control system, on-board I/Os and expandable I/O cards reduce hardware costs and make system integration easier.

Ten automation solutions in the time it would take for one

Lean engineering offers particularly exciting opportunities for machine manufacturers as it allows them to put in place up to ten automation solutions in the time it would normally take for one. As a result, they can step up the pace instantly and ultimately increase their turnover. Independent investigations and empirical findings show that the PLC programming and commissioning work for a flying cutter takes slightly more than a man-week. With SMC, the same result can be achieved in just four man-hours.

With a single command, SMC controls complete motion sequences which the user arranges one after another. These sequences are based on a wealth of automation experience in areas ranging from wood processing to the packaging industry and can cope with simple and moderately complex tasks in a virtually universal manner. With pre-defined commands, users can achieve independent positioning axes, axis and master axis couplings, synchronous axis operation, cam profile applications and sequential movements. Applications range from handling systems, processing stations and test stands to flying cut-off. A wide range of special functions are available: With just a few lines, users can activate head cutting, parts movements, maximum lifting routines, reverse optimization, short length processing and other functions.

90 percent faster engineering – with SMC for IndraDrive, axis couplings, synchronous axes and sequential motion sequences can be achieved much more quickly.

With SMC, users can achieve independent positioning axes, axis and master axis couplings, synchronous axis operation, cam disc applications and sequential movements with pre-defined commands.

Eight commands replace 200 lines of PLC code

When engineering, routine tasks such as defining operating modes, diagnostics and error handling take up significant amounts of time. Up until now, these tasks which are often unpopular accounted for up to two thirds of overall programming time although they barely contribute towards the specific solution. With the SMC option, the drives are pre-configured in the factory, thus eliminating these routine tasks. Thanks to this pre-configuration, users can begin task programming and commissioning straight away.

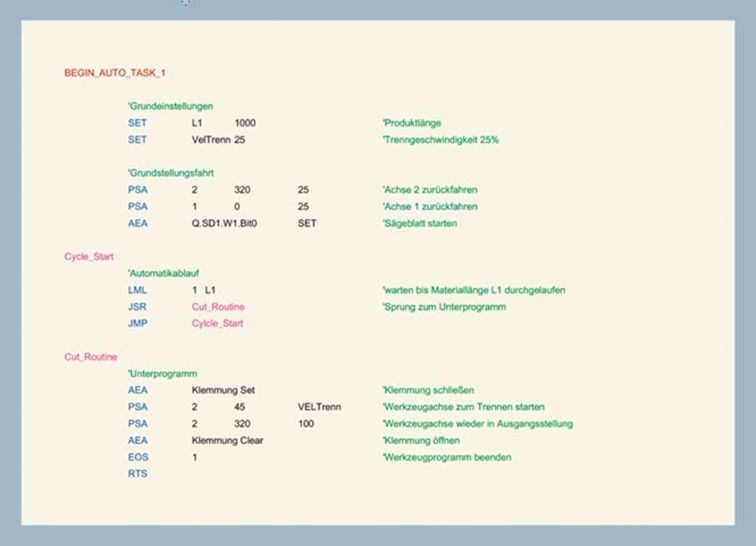

Sequential programming also helps less experienced technicians to create automation solutions geared to particular applications quickly. A practical example: in an open PLC such as the IEC 61131-3, the programming code for a pair of flying shears is more than 200 lines long. With SMC, the user arranges eight commands one after another and then only needs to optimize the processing procedure. Users merely need to learn around 70 commands. They include complete applications and command up to six axes at the same time with one instruction. Users issue step and motion control commands, use closed-loop force and torque controls and query I/Os.

PLC code with just eight commands reduced to 14 lines. With SMC, programming and commissioning a pair of flying shears takes less than half a day.

Optimizing variables directly

SMC includes a manual mode for setting up and referencing axes, a parameterization mode and an automatic mode for working through the programs. In automatic mode, the solutions can control up to four tasks in parallel. At the same time, a cyclic task allows statuses and diagnoses to be called up at any time. Users can therefore observe and optimize variables while the program is running.

Quick solutions for emerging markets

The level of automation in China and other emerging markets is increasing very quickly at the moment. At the same time, there is a lack of programmers with an expert knowledge of PLC in these countries. With online help, watch-listen and tools for debugging or program management, the free SMC Editor helps even technicians with little experience. If necessary, users can use ready-made templates for visualization or create their own.

Owing to increasingly short product life cycles, rapid automation is also becoming more important in mature markets. Concepts such as Bosch Rexroth’s Factory of the Future are highly flexible and allow the production of very small quantities – even down to a batch size of 1. In the future, end users will be able to adapt their production lines flexibly according to orders at very short intervals and will require new motion sequences and additional processing stations at short notice.

The new processing stations must also fit into connected production lines. As a result, an open system for sharing data and information with other machines and higher-level IT systems is a must. The Sercos automation bus allows real-time cross-communication – an important requirement when it comes to precise synchronization with other process movements. Via software, the user selects in the multi-Ethernet interface one of the common protocols such as Sercos, PROFINET IO, EtherNet/IP and EtherCAT as well as the safety protocols CIP Safety on Sercos, Fail Safe over EtherCat and PROFIsafe on PROFINET.

Another task which only very experienced programmers were able to cope with relates to machine safety. Rexroth’s SafeMotion reduces the time required with certified safety functions. As a result, users do not need any additional safety control system in order to meet the requirements and standards of the Machinery Directive.

Increasing turnover with existing resources

The lack of skilled labor will remain a problem for the global mechanical engineering sector in the long term. SMC is a practically oriented approach for simplifying programming and commissioning. Machine manufacturers can therefore significantly increase the number of automation solutions that they supply even without additional PLC programmers. At the same time, the available specialists can concentrate on automating more complex tasks and here too reduce the time to market considerably.

CMA/Flodyne/Hydradyne is an authorized Bosch Rexroth distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

CMA/Flodyne/Hydradyne is an authorized Bosch Rexroth distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.

= 2.74 lb-ft or 3.715_Nm (1.35582_Nm/lb-ft.)

= 2.74 lb-ft or 3.715_Nm (1.35582_Nm/lb-ft.)