Guest contributor: Dave Bird, Balluff

Walk into any die shop in the US and nine out of ten times, we discover diffuse reflective sensors being used to detect a large part or a small part exiting a die. Many people have success using this methodology, but lubrication-covered tumbling parts can create challenges for diffuse-reflective photoelectric sensing devices for many reasons:

- Tumbling parts with many “openings” on the part itself can cause a miss-detected component.

- Overly-reflective parts can false triggering of the output.

- Dark segments of the exiting part can cause light absorption. Remember, a diffuse sensors sensing distance is based on reflectivity. Black or dark targets tend to absorb light and not reflect light back to the receiver.

- Die lube/misting can often fog over a photoelectric lens requiring maintenance or machine down time.

The solution: Super Long Range Inductive Sensors placed under chutes

Most metal forming personnel are very familiar with smaller versions of inductive proximity sensors in tubular sizes ranging from 3mm through 30mm in diameter and with square or “block style” inductive types (flat packs, “pancake types”, etc.) but it is surprising how many people are just now discovering “Super Long Range Inductive Proximity” types. Super Long Range Inductive Proximity Sensors have been used in metal detection applications for many years including Body-In-White Automotive applications, various segments of steel processing and manufacturing, the canning industry, and conveyance.

Benefits of Using A UHMW Chute + Super Long Range Inductive Proximity Sensor in Part Exit/Part-Out Applications:

- It is stronger and quieter than parts flowing over a metal chute, readily available in standard and custom widths, lengths and thicknesses to fit the needs of large and small part stampers everywhere.

- UHMW is reported to be 3X stronger than carbon steel.

- UHMW is resistant to die lubes.

- UHMW allows Super Long Range Inductive Proximity Sensors to be placed underneath and to be “tuned” to fit the exact zone dimension required to detect any part exiting the die (fixed ranges and tunable with a potentiometer). The sensing device is also always out of harm’s way.

- Provides an option for part detection in exiting applications that eliminates potential problems experienced in certain metal forming applications where photoelectric sensing solutions aren’t performing optimally.

Not every Part Exit/Part-Out application is the same and not every die, stamping application, vintage of equipment, budget for sensing programs are the same. Butit’s important to remember in the world of stamping, to try as consistently as possible to think application specificity when using sensors. That is, putting the right sensing system in the right place to get the job done and to have as many technical options available as possible to solve application needs in your own “real world” metal forming operation. We believe the UHMW + Super Long Range Inductive System is such an option.

You can learn more in the video below or by visiting www.balluff.us.

![]() CMA/Flodyne/Hydradyne is an authorized Balluff distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

CMA/Flodyne/Hydradyne is an authorized Balluff distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.

As tabletop automation development progresses, performance demands are increasing to the point that steppers systems may struggle to meet requirements. Fortunately, the addition of an external linear encoder for direct position feedback can enhance a stepper system to enable the expected level of reliable accuracy. An external linear encoder puts drive-mechanism non-linearity inside the control loop, meaning any deviations caused by drive component inaccuracy are automatically corrected and compensated by the overall closed-loop positioning system. In addition, the external linear encoder provides another level of assurance that the driven element has actually moved to the position indicated by the number of stepper pulses and/or the movement reported by the motor encoder. This prevents position errors due to stepper motor stalling, lost counts on the motor encoder, someone manually moving the mechanism against motor torque, or drive mechanism malfunction, i.e. broken drive belt or sheared/skipped gearing.

As tabletop automation development progresses, performance demands are increasing to the point that steppers systems may struggle to meet requirements. Fortunately, the addition of an external linear encoder for direct position feedback can enhance a stepper system to enable the expected level of reliable accuracy. An external linear encoder puts drive-mechanism non-linearity inside the control loop, meaning any deviations caused by drive component inaccuracy are automatically corrected and compensated by the overall closed-loop positioning system. In addition, the external linear encoder provides another level of assurance that the driven element has actually moved to the position indicated by the number of stepper pulses and/or the movement reported by the motor encoder. This prevents position errors due to stepper motor stalling, lost counts on the motor encoder, someone manually moving the mechanism against motor torque, or drive mechanism malfunction, i.e. broken drive belt or sheared/skipped gearing.

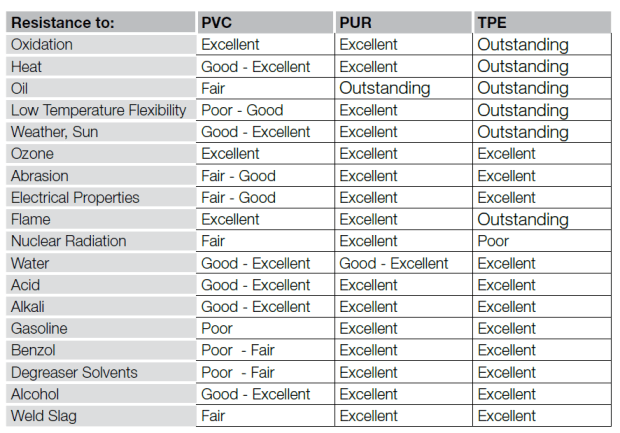

PUR is found mostly in Asia and Europe. This cable jacket type has good resistance against abrasion, oil and ozone. PUR is known for being Halogen free, not containing: chlorine, iodine, fluorine, bromine or astatine. This jacket type does have limited temperature range compared to the other jacket types, -40…80⁰C.

PUR is found mostly in Asia and Europe. This cable jacket type has good resistance against abrasion, oil and ozone. PUR is known for being Halogen free, not containing: chlorine, iodine, fluorine, bromine or astatine. This jacket type does have limited temperature range compared to the other jacket types, -40…80⁰C.

Ask 10 engineers working in Food & Beverage manufacturing what “washdown” means to them and you will probably get about 12 answers. Ask them why they wash down equipment and a more consistent answer appears, everyone is concerned about making clean healthy food and they want to reduce areas of harborage for bacteria. These environments tend to be cool & wet which usually leads the engineers to ask for 316L stainless steel & ingress protection of IP69K from component manufacturers and also ask for special component ratings.

Ask 10 engineers working in Food & Beverage manufacturing what “washdown” means to them and you will probably get about 12 answers. Ask them why they wash down equipment and a more consistent answer appears, everyone is concerned about making clean healthy food and they want to reduce areas of harborage for bacteria. These environments tend to be cool & wet which usually leads the engineers to ask for 316L stainless steel & ingress protection of IP69K from component manufacturers and also ask for special component ratings. What requirements are put onto components exposed to washdown?

What requirements are put onto components exposed to washdown?