Is it possible to safely switch off cylinders while simultaneously transmitting field data and set up the system in accordance with standards? Yes!

In order to rule out a safety-critical fault between adjacent printed circuit board tracks/contact points (short circuit) according to DIN EN ISO 13849, clearance and creepage distances must be considered. One way to eliminate faults is to provide galvanic isolation by not interconnecting safety-relevant circuits/segments. This means charge carriers from one segment cannot switch over to the other, and the separation makes it possible to connect the safety world with automation — with IO-Link. Safely switching off actuators and simultaneously collecting sensor signals reliably via IO-Link is possible with just one module. To further benefit from IO-Link and ensure safety at the same time, Balluff’s I/O module is galvanically isolated with a sensor and an actuator segment. The two circuits of the segments are not interconnected, and the actuator segment can be safely switched off without affecting the sensors. Important sensor data can still be monitoring and communicated.

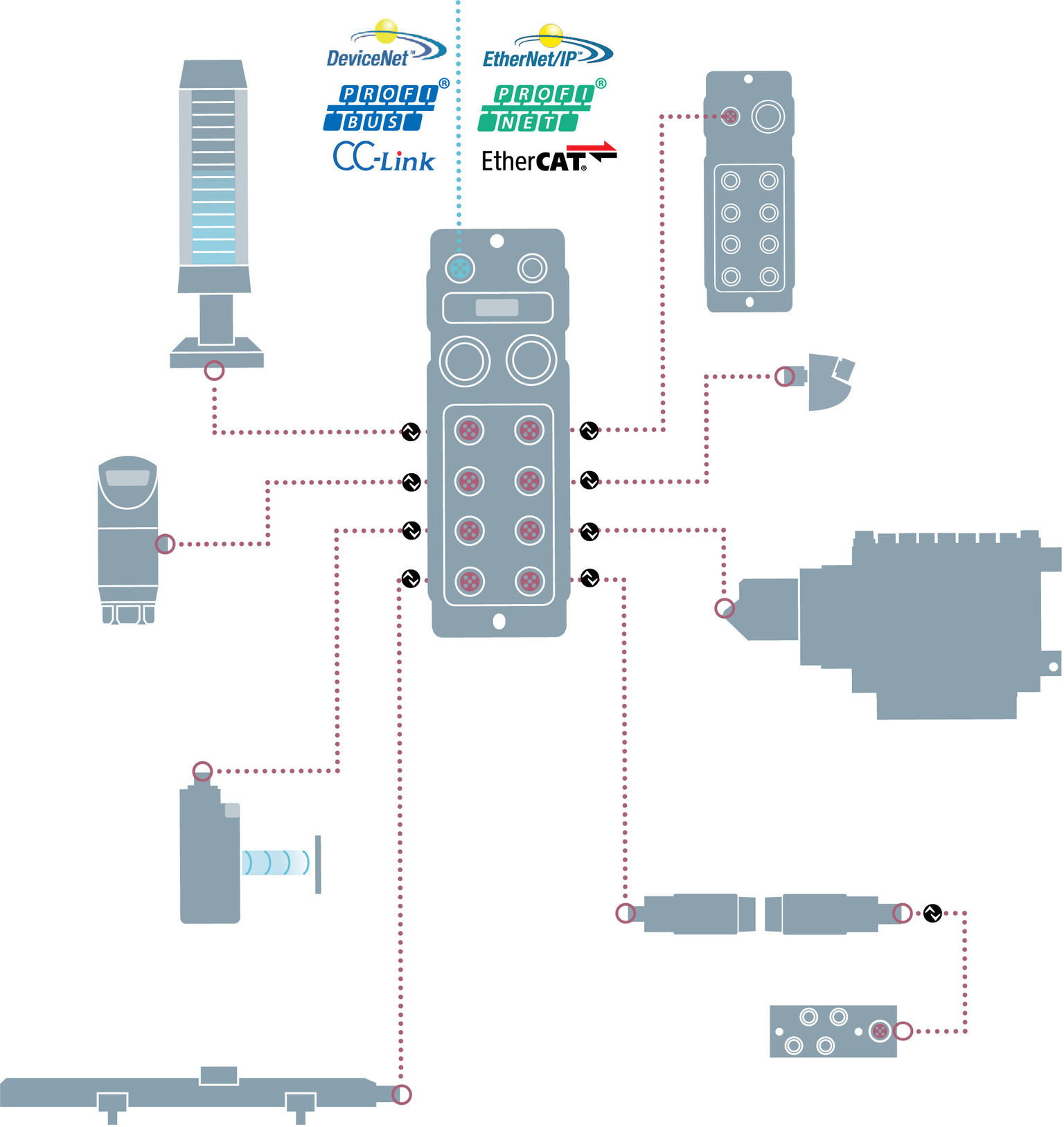

The topological structure and the application of this safety function is shown in this figure as an example:

- A PLC is connected to an IO-Link master module via a fieldbus system.

- The IO-Link master is the interface to all I/O modules (IO-Link sensor/actuator hubs) or other devices, such as IO-Link sensors. The IO-Link communication takes place via a standardized M12 connector.|

- Binary switching elements can be connected to the galvanically isolated sensor/actuator hub (BNI IOL-355). The four connection ports on the left correspond to the sensor segment and the four ports on the right correspond to the actuator segment. Communication of the states is done via IO-Link.

- The power supply for both segments takes place via a 7/8″ connection, whereby attention must be paid to potential separated routing of the sensor and actuator circuits. Both the power supply unit itself and the wiring to the IO-Link device with the two segments must also ensure external galvanic isolation. This is made possible by separating the lines with a splitter.

- An external safety device is required to safely interrupt the supply voltage of the actuator segment (four ports simultaneously). Thus, the module can implement safety functions up to SIL2 according to EN62061/PLd and ISO 13849.

For example, this can happen through the use of a safety relay, whereby the power supply is safely disconnected after actuation of peripheral safety devices (such as emergency stops and door switches). At the same time, the sensor segment remains active and can provide important information from the field devices.

The module can handle up to eight digital inputs and outputs. If the IO-Link connection is interrupted, the outputs assume predefined states that are retained until the IO-Link connection is restored. Once the connection is restored, this unique state of the machine can be used to continue production directly without a reference run.

An application example for the interaction of sensors and actuators in a safety environment is the pneumatic clamping device of a workpiece holder. The position feedback of the cylinders is collected by the sensor segment, while at the same time the actuator segment can be switched off safely via its separately switchable safety circuit. If the sensor side is not required for application-related reasons, galvanically isolated IO-Link modules are also available with only actuator segments (BNI IOL 252/256). An isolated shutdown can protect up to two safety areas separately.

CMA/Flodyne/Hydradyne is an authorized Balluff distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

CMA/Flodyne/Hydradyne is an authorized Balluff distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.

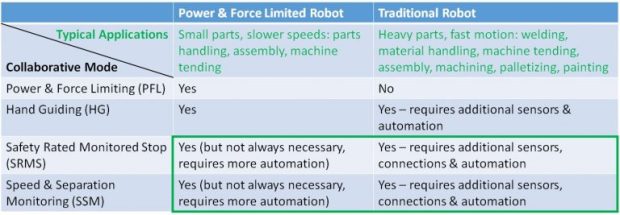

The typical machine/robot guarding scheme of the past used fences or hard guards to separate the human from the machine. Doors were controlled with safety interlock switches, which required the machine to stop on access, such as to load/unload parts or to perform maintenance or service, and this reduced productivity. It was also not 100% effective because workers inside a machine area or work cell might not be detected if another worker restarted the stopped machine. Other drawbacks included the cost of space, guarding, installation, and difficultly changing the work cell layout once hard guarding had been installed.

The typical machine/robot guarding scheme of the past used fences or hard guards to separate the human from the machine. Doors were controlled with safety interlock switches, which required the machine to stop on access, such as to load/unload parts or to perform maintenance or service, and this reduced productivity. It was also not 100% effective because workers inside a machine area or work cell might not be detected if another worker restarted the stopped machine. Other drawbacks included the cost of space, guarding, installation, and difficultly changing the work cell layout once hard guarding had been installed.

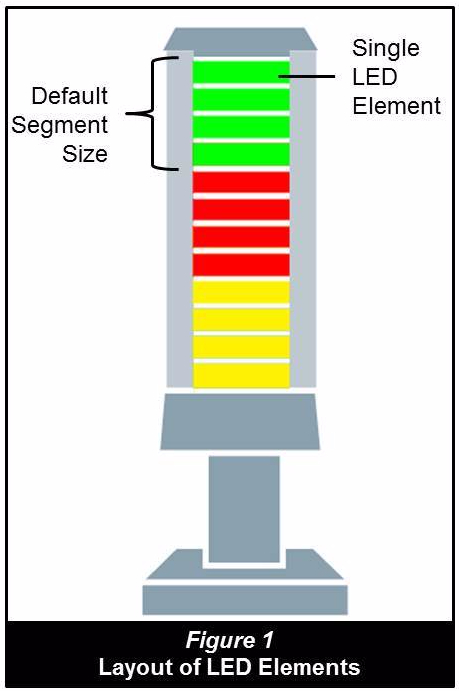

possible to define the segments as you see fit. It works by taking control of every LED element. Each SmartLight segment is comprised of four LED elements that can be controlled anyway you want (see Figure 1). For example, with the 3-segment SmartLight, you actually have 12 LED elements that you can organize any way you want. In Figure 2, we only use three LED elements per SmartLight segment, making it a four segment SmartLight. By using two LED elements we create six segments. Figure 3 is even more interesting, in this example we can see the size of the segments are sized by the intended users. Forklift Drivers need a larger light due to the distance and the fact that they are moving. Operators are closer than the forklift drivers, so their segment can be smaller, and maintenance can use the smallest segments because they are closest to the SmartLight when working on the machine.

possible to define the segments as you see fit. It works by taking control of every LED element. Each SmartLight segment is comprised of four LED elements that can be controlled anyway you want (see Figure 1). For example, with the 3-segment SmartLight, you actually have 12 LED elements that you can organize any way you want. In Figure 2, we only use three LED elements per SmartLight segment, making it a four segment SmartLight. By using two LED elements we create six segments. Figure 3 is even more interesting, in this example we can see the size of the segments are sized by the intended users. Forklift Drivers need a larger light due to the distance and the fact that they are moving. Operators are closer than the forklift drivers, so their segment can be smaller, and maintenance can use the smallest segments because they are closest to the SmartLight when working on the machine.

in close proximity, usually within the work envelope of the operators. In the example shown, the SmartLight is used in a socket tray application. The SmartLight indicates to the operator which socket is required for a specific task. Inductive proximity sensors connected to an IO-Link Hub verify the correct socket was pulled. The photo is showing an All-Call (all lights lit). Here you can see the unique LED element grouping only available with the new Flexible mode. Other applications for operator guidance are essentially endless. There are no technical limitations to your creativity.

in close proximity, usually within the work envelope of the operators. In the example shown, the SmartLight is used in a socket tray application. The SmartLight indicates to the operator which socket is required for a specific task. Inductive proximity sensors connected to an IO-Link Hub verify the correct socket was pulled. The photo is showing an All-Call (all lights lit). Here you can see the unique LED element grouping only available with the new Flexible mode. Other applications for operator guidance are essentially endless. There are no technical limitations to your creativity.

builders and discrete manufacturers. For machine builders, the biggest advantage comes from the simplified wiring scheme of IO-Link devices. We have seen machine builder users of IO-Link reduce their wiring hardware & labor costs by 30%-60% for sensors,

builders and discrete manufacturers. For machine builders, the biggest advantage comes from the simplified wiring scheme of IO-Link devices. We have seen machine builder users of IO-Link reduce their wiring hardware & labor costs by 30%-60% for sensors,