Guest contributor: Marty Hegyi Product Manager, Cylinders, Bosch Rexroth Corp.

Here’s how to design hydraulic cylinders that improve performance, last longer and cost less.

Hydraulic cylinders harness fluid pressure and flow to generate linear motion and force, and they work well in both industrial machines, like presses and plastic-molding machines, and in mobile equipment, like excavators and mining trucks. And when compared with pneumatic, mechanical or electric linear-motion systems, hydraulics can be simpler, more durable and offer significantly greater power density.

Bosch Rexroth builds large hydraulic cylinders with bores to 1.5m and strokes to 24 m

Hydraulic cylinders are available in an impressive array of types and sizes to meet a wide range of application needs. Choosing the right cylinder is critical for maximum performance and reliability. Here are 12 practical tips for selecting, sizing and operating the best one for a job.

Selection considerations

1. Choose the right cylinder type. Two basic hydraulic cylinder designs for industrial applications are tie-rod and welded cylinders.

Tie-rod cylinders use high-strength threaded steel tie rods on the outside of the cylinder housing for additional strength and stability. In the U.S., this is the most common cylinder type. They’re used on most general industrial applications, such as plastics machinery and machine tools, although they tend to be limited to 3,000 psi maximum operating pressure. The cylinders are built to NFPA standards, which makes their dimensions and pressure ratings interchangeable with any other cylinder built to that standard.

Welded or mill-type cylinders have a heavy-duty housing with a barrel welded or bolted directly to the end caps and require no tie rods. Designed for higher pressures, to 5,000 psi

Mill-type cylinders have a heavy-duty housing with a barrel welded or bolted directly to the end caps

Mill -type cylinders have a heavy-duty housing with a barrel welded or bolted directly to the end caps and require no tie-rods

or greater, they are generally preferred in more-rugged applications such as presses, steel mills and offshore settings with harsh environments and wide temperature swings.

Unlike U.S. OEMs, European manufacturers typically use mill-type cylinders in almost all general industrial applications. (They also use tie-rod cylinders, but generally for lower-pressure tasks up to 160 bar (2,350 psi).) However, due to the design, tie-rod cylinders are less expensive than mill-type cylinders—another reason for widespread use in the U.S.

Also keep in mind that cylinders are often customized. NFPA cylinder standards dictate dimensions, pressure ratings, type of mountings, and so on—they’re standard catalog products. However, engineers designing custom machinery often need to deviate from the standards with special mountings, port sizes or configurations to suit a particular application. About 60% of the cylinders sold in the U.S. are catalog items, while 40% are modified products with unique requirements.

2. Select the proper mountings. Mounting methods also play an important role in cylinder performance. The cylinder mounting method first depends on whether the cylinder body is stationary or pivots.

For stationary cylinders, fixed mounts on the centerline of the cylinder are usually best for straight-line force transfer and minimal wear. Among the different variations, flange mounts are generally preferred. Loads are centered on the cylinder and opposing forces are equally balanced on rectangular or round flanges. They’re strong and rigid, but have little tolerance for misalignment. Experts recommend cap-end mounts for thrust loads and rod-end mounts for pull loads.

Centerline lug mounts also absorb force on the centerline, but require dowel pins to secure the lugs to prevent movement at higher pressures or under shock conditions.

Side-mounted or foot-mounted cylinders are relatively easy to install and service, but

Tie-rod cylinders have high-strength threaded steel tie rods on the outside of the cylinder housing for added strength and stability

they generate offset loads. The mounts experience a bending moment as the cylinder applies force to a load, potentially increasing wear and tear. Heavy loading tends to make long-stroke, small-bore cylinders unstable.

Side and foot mounts need to be well aligned and on the same plane, and the load supported and guided. Otherwise, induced side loads due to misalignment lead to cylinder wear and seal leaks. Engineers also must be concerned with shear forces on the bolts. Add a dowel or shear pin and keyway behind the feet to prevent the forces from potentially shearing the mounting bolts. If necessary for extra support, add another set of foot mounts in the cylinder midsection in addition to those on the head and cap ends.

3. Select the right pivot mountings when the cylinder body moves. Pivot mounts absorb force on the cylinder centerline and let a cylinder change alignment in one plane. Common types include clevis, trunnion and spherical-bearing mounts.

Clevis mounts can be used in any orientation and are generally recommended for short strokes and small to medium-bore cylinders. Cylinder engineers prefer clevis mounts with spherical bearings over those with plain bearings because they allow for a bit more misalignment and are, thus, a bit more forgiving. However, if using a spherical bearing on a rear clevis, they also recommend a rod-end attachment that pivots—such as a spherical rod eye. The combination helps compensate for any side loading or potential misalignment.

Trunnion mounts come in head, mid and rear-mount versions. The mid-trunnion design is likely most common, as it offers designers a bit more flexibility. They can be specified exactly in the cylinder mid-section or most anywhere toward the front or rear as the application demands. Once specified, however, the mount is not adjustable.

Sizing considerations

For all types of cylinders, important parameters include stroke, bore diameter, rod diameter and pressure rating.

4. Piston-rod diameter is critical. Perhaps the most common error in hydraulic design is underspecifying the piston rod, making a cylinder more prone to stress, wear and failure. Piston-rod diameters can range from 0.5 to more than 20 in., but they must be sized for the available loads. In a push application, it is extremely important to size the rod diameter properly, based on Euler calculations, to avoid rod buckling or bending.

When designing a cylinder to generate a required force, sizing the rod is always the first consideration. From there, work backward and determine bore size for the available pressure, and so on.

5. Prevent rod bending. In cylinders with long strokes, a fully extended rod can bend under its own weight. Excessive bending leads to wear and damage to seals and bearings. It could even cock the piston inside the bore, which can score and damage the inner surface of the cylinder. Rod deflection should never exceed 1 to 2 mm.

Cylinder rods that are at risk for bending or misalignment require additional support. Depending on the stroke length, a stop tube—which increases the bearing area of the cylinder—may be required to prevent excessive wear and jack-knifing. Engineers might also consider a larger diameter rod, which increases strength. But that also increases weight and may be self-defeating, so do the math carefully. In extreme cases, users may also need to add external mechanical support for the rod, such as a saddle-type bearing.

6. Watch out for impact loads. Stroke length, the distance needed to push or pull a load, can vary from less than an inch to several feet or more. But when the cylinder extends or retracts, ensure that the piston doesn’t bottom out and generate impact loads at the end of stroke. Engineers have several options: Add internal cushions to decelerate the load near the end of stroke; add an external mechanical stop that prevents the cylinder from bottoming out; or use proportional-valve technology to precisely meter flow and safely decelerate the load.

7. Weigh bore diameter versus operating pressure. To produce a given amount of force, engineers can specify large-bore cylinders that operate at low pressures, or vice versa. Generally, systems that operate at higher pressures but with smaller cylinders are more cost effective. Also the benefits cascade. Smaller cylinders require less flow and, in turn, smaller pumps, lines, valves and so on. Many installations see an overall cost reduction by moving to higher pressures.

That said, cylinders are rated for both nominal (standard) pressure and test pressure to account for variations. Systems should never exceed the nominal rated design pressure of a cylinder.

8. Add a factor of safety. While design calculations are essential, real-world operations differ from theoretical results. Always assume peak loads will require additional force. The rule of thumb is to choose a cylinder with a tonnage rating of 20% more than required for the load. That compensates for losses like friction from the load, efficiency losses in the hydraulics, actual pressure below the rated system pressure, slip-stick on cylinder seals and bearings, and so on.

Operating considerations

Cylinder parameters like stroke and force must match machine requirements, but that is only half the challenge. Environmental and operating demands also play a major part in determining a cylinder’s ultimate success.

9. Match the seals to the job.Seals are probably the most vulnerable aspect of a hydraulic system. Proper seals can reduce friction and wear and increase service life, while the wrong seal leads to downtime and maintenance headaches. It probably goes without saying, but ensure the seal material is compatible with the fluid. Most hydraulics use a form of mineral oil, and standard Buna-N seals tend to work well. But applications involving synthetic fluids, such as phosphate esters, require Viton seals. Polyurethane is also incompatible with high water-based fluid such as water glycol.

Regardless of the fluid, keep it clean. Contamination and dirt in the fluid will damage  seals. It can also score the inside of the barrel and eventually ruin the cylinder.

seals. It can also score the inside of the barrel and eventually ruin the cylinder.

If operating temperatures exceed 300° F, standard Buna-N nitrile rubber seals may fail. Viton synthetic rubber seals generally handle temperatures to 400° F and fluorocarbon seals even higher. When in doubt, assume conditions will be worse than they first appear.

10. Add a gland drain. Probably 90% of cylinder failures are due to the seals. That holds even if engineers specify the proper seals for the fluid, pressure, environment and application as they wear out over time and need replacement. Most experts recommend that seals should be maintained periodically, rather than waiting for failure at a usually inopportune time.

If cylinders are in hard-to-access locations that makes maintenance difficult, or if leaks will damage products or lead to costly downtime, order cylinders with a “gland drain.” This is a special port machined into the cylinder head between primary and secondary seals; or between primary and rod wiper. Then, if the primary rod seal begins to fail and leak, oil bypasses the seal and flows out the gland-drain port—generally through tubing to a collection bottle. If oil collects in the normally empty bottle, it gives a visual indication that seals are wearing out and will soon need replacement.

Cylinders usually have a secondary rod seal or a double-lip rod wiper that temporarily prevents oil from leaking out the rod end, giving maintenance personnel time to schedule repairs.

11. Watch the materials. The type of metal used for the cylinder head, base and bearing can make a significant difference. Most cylinders use SAE 660 bronze for rod bearings and medium-grade carbon steel for heads and bases, which is adequate for many applications. But stronger material, such as 65-45-12 ductile iron for rod bearings, can provide a sizable performance advantage for tough industrial tasks.

Also consider extreme temperatures. Typical carbon steels used in cylinder components are generally suited for around –5 to 200° F. In arctic conditions well below 0° F, for example, standard steel can become brittle and may require alternative materials.

12. Protect the rod. Because the piston rod meets the outside environment, it must resist attack from water, salt air, corrosives, and other harmful substances. In general industrial applications, carbon steel with chrome plating is the norm. But in wet or high humidity environments, such as marine hydraulics, 17-4PH stainless steel with chrome plating is used for most piston rods. Some cylinder manufacturers offer special protective coatings. Bosch Rexroth, for example, offers Enduroq, which is a proprietary thermal-spray coating or plasma-welded overlay that’s applied to rods for extreme corrosion protection and high wear resistance. It’s used in harsh environments, typically for specialty large-bore, long-stroke cylinders.

For dirty, abrasive conditions, engineers have a love/hate relationship with protective rod boots. Installing a boot over the rod keeps out dirt, metal shavings and other external contamination that would otherwise damage the rod and eventually the seals. However, if the boot punctures or rips, dirt gets drawn in and may not get out, which is worse than no boot at all. Maintenance personnel must routinely check for worn or torn boots that could accelerate damage to the cylinder.

Don’t overlook sizing software

Sizing software for cylinders is a great tool, but more engineers need to take advantage of the benefits it offers. These programs address most, if not all, of the pertinent questions designers need to answer to spec the right cylinder.

One such program developed by Bosch Rexroth is the Interactive Catalog System  (www.boschrexroth.com/ics). It lets users enter parameters like force, pressure, load, angle of installation and mounting type, and the software sizes the cylinder, lists variations that meet the criteria and offers possible alternatives. It also lets engineers select and test cylinders on-screen before specifying the actual components. In addition, ICS generates dimensional drawings and 2D or 3D models for direct import into AutoCAD or other CAD software.

(www.boschrexroth.com/ics). It lets users enter parameters like force, pressure, load, angle of installation and mounting type, and the software sizes the cylinder, lists variations that meet the criteria and offers possible alternatives. It also lets engineers select and test cylinders on-screen before specifying the actual components. In addition, ICS generates dimensional drawings and 2D or 3D models for direct import into AutoCAD or other CAD software.

CMAFH Resources

Shop online for Rexroth hydraulic products here

![]()

Powerlink, Profibus

Powerlink, Profibus Multi -zone tension control

Multi -zone tension control

As tabletop automation development progresses, performance demands are increasing to the point that steppers systems may struggle to meet requirements. Fortunately, the addition of an external linear encoder for direct position feedback can enhance a stepper system to enable the expected level of reliable accuracy. An external linear encoder puts drive-mechanism non-linearity inside the control loop, meaning any deviations caused by drive component inaccuracy are automatically corrected and compensated by the overall closed-loop positioning system. In addition, the external linear encoder provides another level of assurance that the driven element has actually moved to the position indicated by the number of stepper pulses and/or the movement reported by the motor encoder. This prevents position errors due to stepper motor stalling, lost counts on the motor encoder, someone manually moving the mechanism against motor torque, or drive mechanism malfunction, i.e. broken drive belt or sheared/skipped gearing.

As tabletop automation development progresses, performance demands are increasing to the point that steppers systems may struggle to meet requirements. Fortunately, the addition of an external linear encoder for direct position feedback can enhance a stepper system to enable the expected level of reliable accuracy. An external linear encoder puts drive-mechanism non-linearity inside the control loop, meaning any deviations caused by drive component inaccuracy are automatically corrected and compensated by the overall closed-loop positioning system. In addition, the external linear encoder provides another level of assurance that the driven element has actually moved to the position indicated by the number of stepper pulses and/or the movement reported by the motor encoder. This prevents position errors due to stepper motor stalling, lost counts on the motor encoder, someone manually moving the mechanism against motor torque, or drive mechanism malfunction, i.e. broken drive belt or sheared/skipped gearing.

seals. It can also score the inside of the barrel and eventually ruin the cylinder.

seals. It can also score the inside of the barrel and eventually ruin the cylinder. (

(

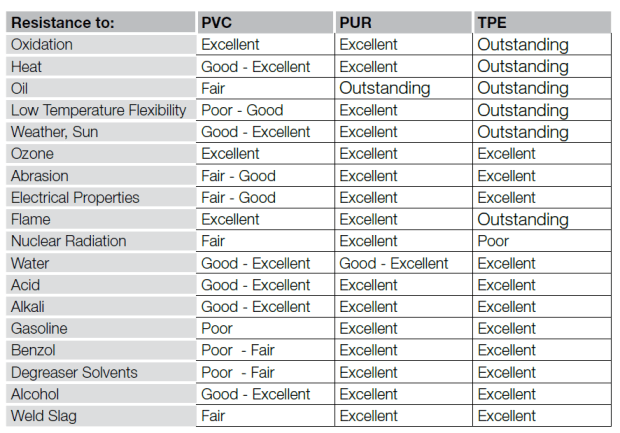

PUR is found mostly in Asia and Europe. This cable jacket type has good resistance against abrasion, oil and ozone. PUR is known for being Halogen free, not containing: chlorine, iodine, fluorine, bromine or astatine. This jacket type does have limited temperature range compared to the other jacket types, -40…80⁰C.

PUR is found mostly in Asia and Europe. This cable jacket type has good resistance against abrasion, oil and ozone. PUR is known for being Halogen free, not containing: chlorine, iodine, fluorine, bromine or astatine. This jacket type does have limited temperature range compared to the other jacket types, -40…80⁰C.