Cabinet-free servo drive technology boasts a number of crucial benefits – simple installation, drastically reduced space requirements, minimum cabling and high flexibility. The ctrlX DRIVE cabinet-free IP65/IP67 system virtually eliminates the control cabinet, thus creating space for modular, lean production systems. Andreas Knops explains the system’s distinguishing features.

ctrlX DRIVE cabinet-free is the latest generation of cabinet-free servo drive technology from Bosch Rexroth. What is different about it?

This solution is the successor to the existing IndraDrive Mi cabinet-free drive system. We develop the entire drive technology portfolio based on the compact and open ctrlX DRIVE technology. Over 20 years of experience in cabinet-free drive technology have gone into ctrlX DRIVE cabinet-free, taking it to a new level.

Key new developments include the expansion of the power increments, the cooling concept and new topology options. We offer the inverters as a single-axis variant in six increments from 6 A to 54 A and as a double-axis variant in five increments from 6 A to 30 A maximum current. With a maximum current of up to 54 A, users are now able to choose whether to realize their machine with a control cabinet, without a control cabinet or with a combination of both variants.

This allows the greatest possible flexibility for both existing and completely new application scenarios.

For which applications is this drive system intended?

ctrlX DRIVE cabinet-free is particularly suitable for machines in which saving space and minimizing cabling are key requirements. It also helps to reduce the machine footprint.

In addition, the drive system supports the realization of modular machine concepts, which pays dividends in both production and later use. In concrete terms, this means that the production of the machine can be modularized more easily and that end users will be able to subsequently expand the machines with additional modules according to their needs.

What specific savings will be achieved?

We calculate the savings made on a case-by-case basis together with our customers. They can be quantified over the entire life cycle based on the machine design, the operating mode and the operating time.

Because the solution almost completely eliminates the control cabinet, the space and cabling required is reduced by up to 90%. This results in a more compact design and provides the option of mounting the device directly, for example on the machine frame. This not only saves time and costs, but also makes assembly, project planning and operation easier.

In addition, the solution enables significant energy savings of up to 70 percent. The decentralized design eliminates energy consumption for control cabinet air-conditioning, which lowers operating costs. In addition, the ctrlX DRIVE cabinet-free version uses silicon carbide semiconductors (SiC technology), which significantly reduce energy losses and thus increase overall energy efficiency. By using SiC semiconductors, power losses can be reduced by up to 60 percent compared to IGBT technology.

Operating the inverters on a common DC link for the purpose of energy exchange also helps increase overall efficiency. Depending on the operating mode of the machine, we also utilize various options – e.g. energy recovery, passive or active energy storage, peak load reduction – to reduce the energy requirement specifically for the respective application.

Why is ctrlX DRIVE cabinet-free designed according to protection class IP65/IP67?

The IP65/IP67 protection rating ensures that the system works reliably even in harsh or extreme conditions – for example, where protection against water jets is required.

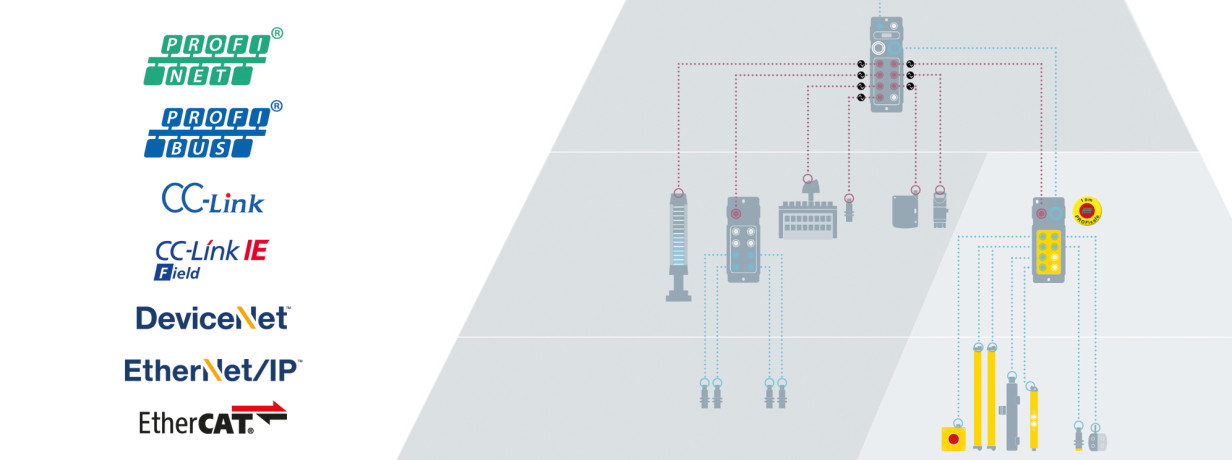

Due to its openness, the drive system can be seamlessly integrated into a wide variety of automation architectures. With all its features and benefits, ctrlX DRIVE speeds up cabinet-free development and commissioning processes – and supports consistently flexible, cost-efficient and energy-saving production.

To learn more, please visit www.boschrexroth.com

CMA/Flodyne/Hydradyne is an authorized Bosch Rexroth distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.