Guest contributor: Henry Menke, Balluff

In many industries, especially in Packaging, the need to minimize capital equipment costs drives engineers to implement low-cost, manual methods of size change (also called format change) on their machinery. In most cases, this means hand-driven cranks with mechanical dial pointers and/or mechanical revolution counters.

While cost is saved on the procurement side, cost is also shifted over to the operational side. Plant management is left with the task of keeping accurate records of various machine set-ups needed to run different products, as well as the task of training machine operators to perform all machine set-ups correctly. It doesn’t always go as smoothly as expected, and machine reformatting can result in longer downtime than planned, machine stoppages, and possibly excessive scrap.

The key to size-change improvement is capturing the linear movements of the machine components and bringing them into the control system, and then providing “smart” visual feedback to the machine operator during setup. For capturing machine position, a robust and cost-effective magnetic linear encoder is ideal. However, traditional linear encoders deliver an A-B quadrature incremental signal, which requires re-homing upon start-up or after a power loss. What’s needed is an absolute encoder signal, but that brings other challenges such as the cost and complexity of implementing an absolute signal like SSI (Synchronous Serial Interface).

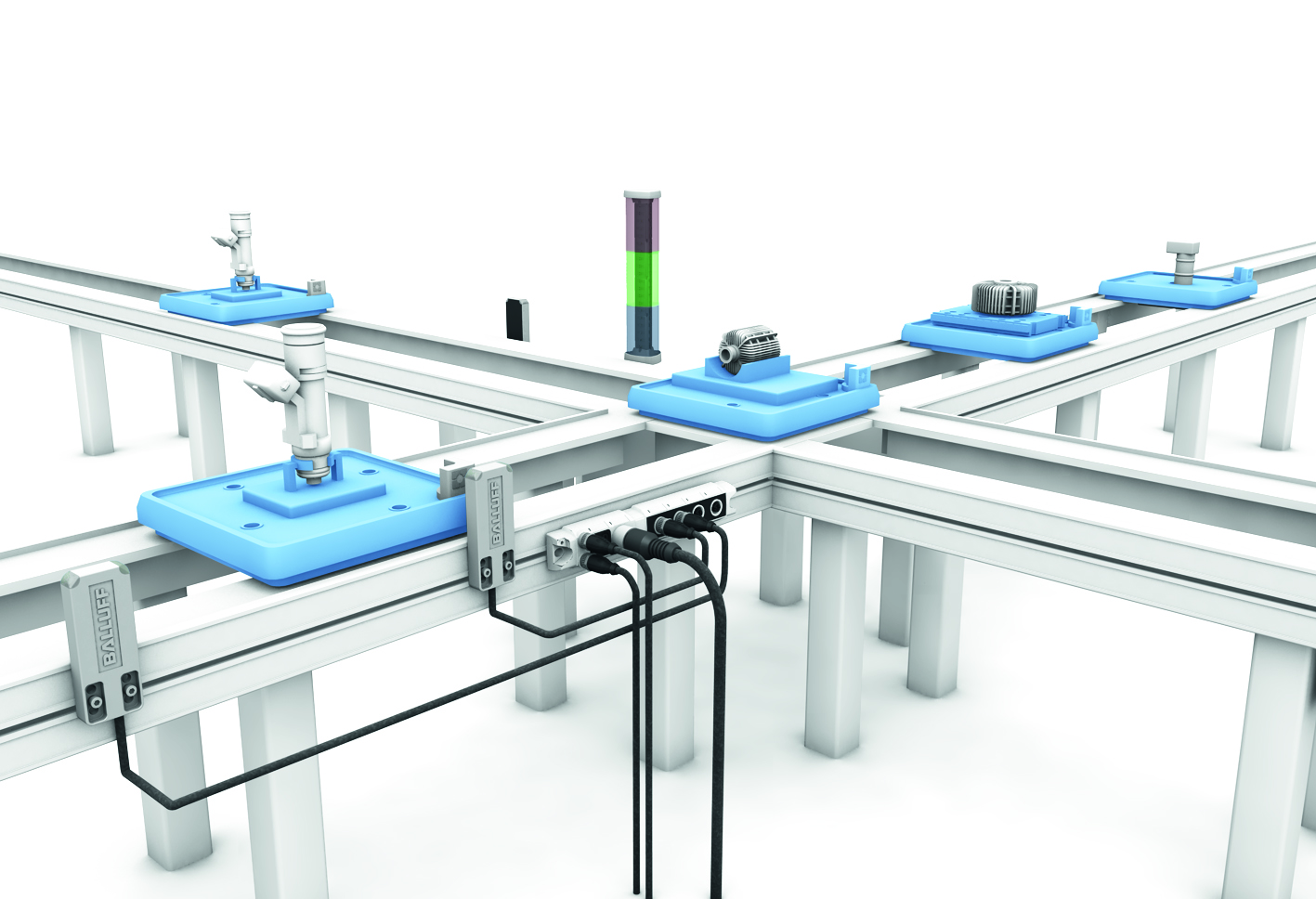

Fortunately, there’s a new encoder interface  option that eliminates the problem of non-absolute feedback and the hassle of absolute position signal interface: IO-Link. IO-Link is a multi-vendor, non-proprietary, device-level serial digital interface that can be aggregated onto today’s Ethernet industrial networks. Magnetic linear encoders are now available that feature absolute position indication combined with the ease and convenience of the IO-Link communication protocol.

option that eliminates the problem of non-absolute feedback and the hassle of absolute position signal interface: IO-Link. IO-Link is a multi-vendor, non-proprietary, device-level serial digital interface that can be aggregated onto today’s Ethernet industrial networks. Magnetic linear encoders are now available that feature absolute position indication combined with the ease and convenience of the IO-Link communication protocol.

Now we just need to provide visual feedback to the machine operator regarding which direction and how far to turn the hand cranks. Once  again, IO-Link provides the answer in the form of an IO-Link-enabled, fully programmable multi-segment LED stack light. When a new machine set up is required, the position parameters are stored in the controller. The controller communicates over IO-Link to the LED stack lights, indicating to the operator which dials need to be turned and in which direction. For example, a horizontally mounted stack light could be lit red on the right half, indicating that the dial needs to be turned to the right. As the position moves closer to the proper setting, the red segments count down until the entire stack light goes green, indicating that the correct position for that axis has been reached. No paper records to maintain and store, and very little training required with the intuitive operator visualization.

again, IO-Link provides the answer in the form of an IO-Link-enabled, fully programmable multi-segment LED stack light. When a new machine set up is required, the position parameters are stored in the controller. The controller communicates over IO-Link to the LED stack lights, indicating to the operator which dials need to be turned and in which direction. For example, a horizontally mounted stack light could be lit red on the right half, indicating that the dial needs to be turned to the right. As the position moves closer to the proper setting, the red segments count down until the entire stack light goes green, indicating that the correct position for that axis has been reached. No paper records to maintain and store, and very little training required with the intuitive operator visualization.

For more information about IO-Link linear encoders click here, and to learn more about IO-Link programmable LED stack lights visit www.balluff.com.

CMA/Flodyne/Hydradyne is an authorized Balluff distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

CMA/Flodyne/Hydradyne is an authorized Balluff distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.

style form factors are used to measure very short distances, typically in the 1…5 mm range. The operating principle is similar to a standard on/off inductive proximity sensor. However, instead of discrete on/off operation, the distance from the face of the sensor to a steel target is expressed as a continuously variable value. Their extremely small size makes them ideal for applications in confined spaces.

style form factors are used to measure very short distances, typically in the 1…5 mm range. The operating principle is similar to a standard on/off inductive proximity sensor. However, instead of discrete on/off operation, the distance from the face of the sensor to a steel target is expressed as a continuously variable value. Their extremely small size makes them ideal for applications in confined spaces.

Laser distance sensors use either a time-of-flight measuring principle (for long range) or triangulation measuring principle (for shorter range) to precisely measure sensor to target distance from up to 6 meters away. Laser distance sensors are especially useful in applications where the sensor must be located away from the target to be measured.

Laser distance sensors use either a time-of-flight measuring principle (for long range) or triangulation measuring principle (for shorter range) to precisely measure sensor to target distance from up to 6 meters away. Laser distance sensors are especially useful in applications where the sensor must be located away from the target to be measured. flexible magnet tape and a compact sensing head to provide extremely accurate position, absolute position feedback over stroke lengths up to 8 meters. Flexible installation, compact overall size, and extremely fast response time make magnetic linear encoders an excellent choice for demanding, fast moving applications.

flexible magnet tape and a compact sensing head to provide extremely accurate position, absolute position feedback over stroke lengths up to 8 meters. Flexible installation, compact overall size, and extremely fast response time make magnetic linear encoders an excellent choice for demanding, fast moving applications.