Guest Contributor: Thomas Fey, Bosch Rexroth

Machine tools are rightly considered to be technology carriers and trailblazers for other industries in mechanical engineering. They frequently are the first to try new technologies and optimize existing ones. For this reason, machinery users expect every new piece of equipment to increase productivity.

The users of machine tools face global competition. When they invest in new machines, they generally have two main issues in mind: cycle times per processing step and throughput times for the completely processed component. At the same time, they continue to increase their requirements for surface quality and tolerances. Machine tool makers respond with higher dynamics in all movements and the integration of additional processing technologies. Increasing numbers of sensors are now monitoring the processing job to create reproducible quality.

These three trends – more speed, more completeness and more precision – place increasing demands on the control system. Every gain in speed requires shorter control cycles. The CNC control unit must provide additional capacities to integrate additional processing stations and technologies. At the same time, data transmissions in a machine are rising inordinately because of the sensors.

In this regard, Bosch Rexroth has significantly raised the bar with its new generation of the CNC system MTX. The smallest version is a compact solution for up to 12 axes. The highest performance level extends all the way to 250 axes with a hardware control system. In the controllers, high-performance, multi-core processors intelligently assign the different tasks for CNC, PLC and communications. Fluctuating processor utilization levels that vary based on the configuration for the application remain non-reactive and ensure constant overall performance. This is important because the CNC system solution provides the shortest PLC and CNC cycle times even as the number of axes rises, even for high-speed processing. In the process, machine manufacturers can significantly increase the dynamics of their products.

At the same time, more and more users, particularly automotive industry suppliers, are investing in production lines for complete processing. To reduce wrapping and handling times, they are looking for multi-technology solutions. For this reason, machine manufacturers are increasingly combining classic processes like drilling, milling and grinding into one system. They are also increasingly adding non-cutting technologies like laser cutting and welding or additive processes. The printed components are given their final shape in subsequent processing. These technologies are sometimes very computationally intensive. They are also done simultaneously with other processing steps. The idea of offsetting these performance peaks by using separate control systems with a machine’s own hardware significantly increases the complexity of automation. The MTX offers sufficient power reserves here to display all currently known uses on hardware. This is also the case for the automation of machine tools. A number of manufacturers have said that between 50 percent and 80 of all machines they deliver have integrated loading and unloading systems. The MTX also takes on this task.

While these trends move forward, machine manufacturers are also increasingly adding more and more sensors. These data support process optimization and monitor the processing in situ. With fast I/O, the MTX ensures that the sensor data are transferred and analyzed in real time. In the process, it lays the foundation for short control cycles that measurably increase the precision of processing and surface quality.

In short: To achieve the classic qualities of increased productivity, all roads lead to higher-performance CNC system solutions. The MTX currently offers the highest computing capacity and system capability for rising demands by offering increased dynamics, technology combinations and amount of sensors.

Learn more: CNC system solution MTX

CMA/Flodyne/Hydradyne is an authorized Bosch Rexroth distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

CMA/Flodyne/Hydradyne is an authorized Bosch Rexroth distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.

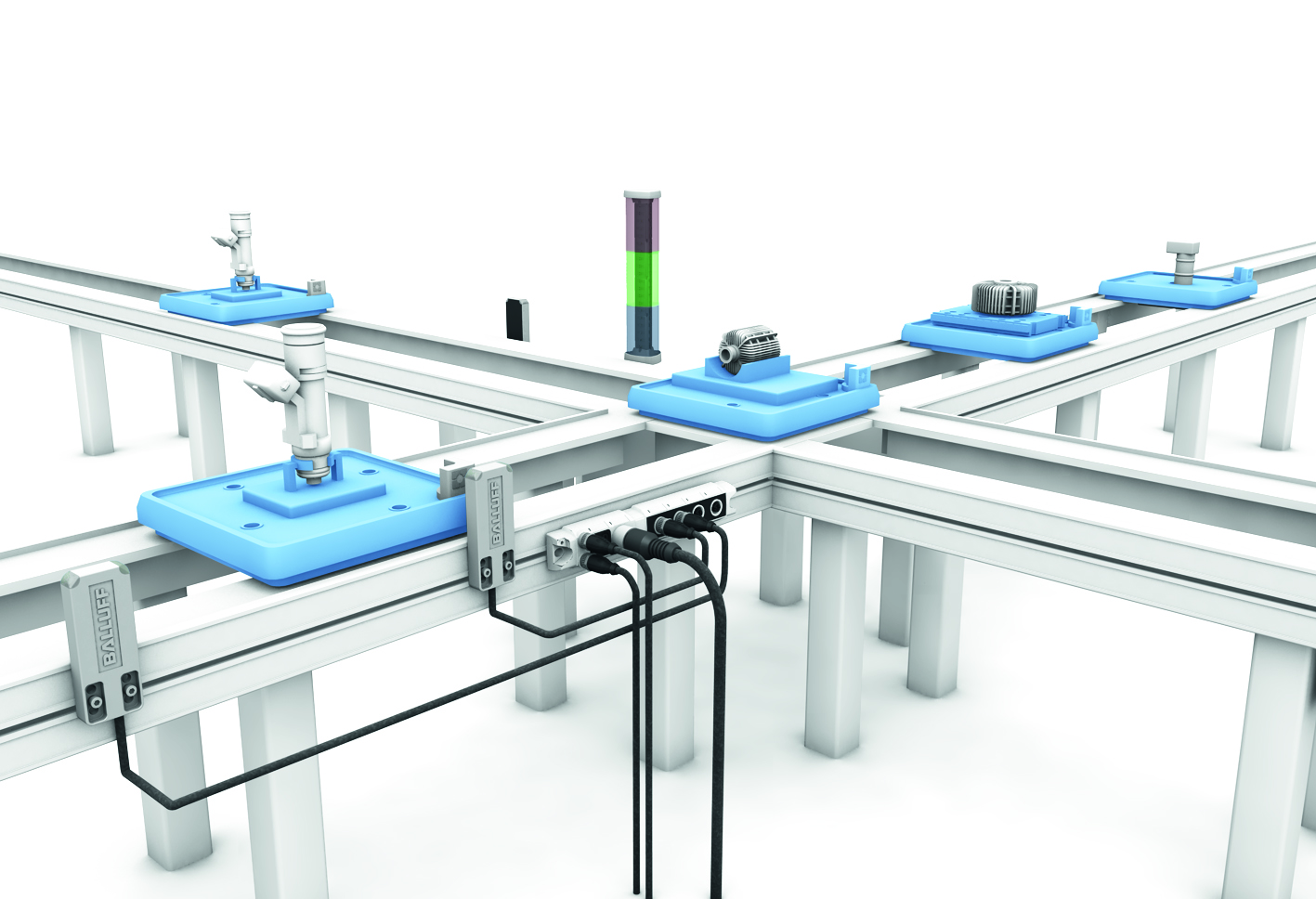

The assembly line at the Hannover Messe.

The assembly line at the Hannover Messe.

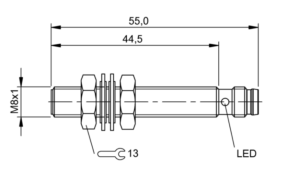

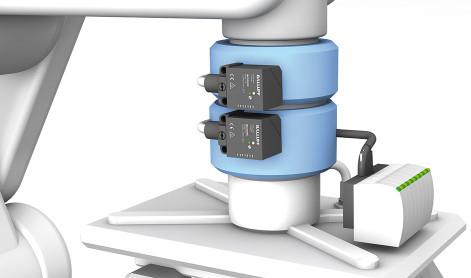

style form factors are used to measure very short distances, typically in the 1…5 mm range. The operating principle is similar to a standard on/off inductive proximity sensor. However, instead of discrete on/off operation, the distance from the face of the sensor to a steel target is expressed as a continuously variable value. Their extremely small size makes them ideal for applications in confined spaces.

style form factors are used to measure very short distances, typically in the 1…5 mm range. The operating principle is similar to a standard on/off inductive proximity sensor. However, instead of discrete on/off operation, the distance from the face of the sensor to a steel target is expressed as a continuously variable value. Their extremely small size makes them ideal for applications in confined spaces.

Laser distance sensors use either a time-of-flight measuring principle (for long range) or triangulation measuring principle (for shorter range) to precisely measure sensor to target distance from up to 6 meters away. Laser distance sensors are especially useful in applications where the sensor must be located away from the target to be measured.

Laser distance sensors use either a time-of-flight measuring principle (for long range) or triangulation measuring principle (for shorter range) to precisely measure sensor to target distance from up to 6 meters away. Laser distance sensors are especially useful in applications where the sensor must be located away from the target to be measured. flexible magnet tape and a compact sensing head to provide extremely accurate position, absolute position feedback over stroke lengths up to 8 meters. Flexible installation, compact overall size, and extremely fast response time make magnetic linear encoders an excellent choice for demanding, fast moving applications.

flexible magnet tape and a compact sensing head to provide extremely accurate position, absolute position feedback over stroke lengths up to 8 meters. Flexible installation, compact overall size, and extremely fast response time make magnetic linear encoders an excellent choice for demanding, fast moving applications.

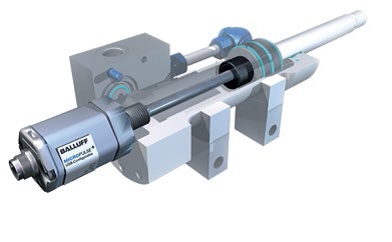

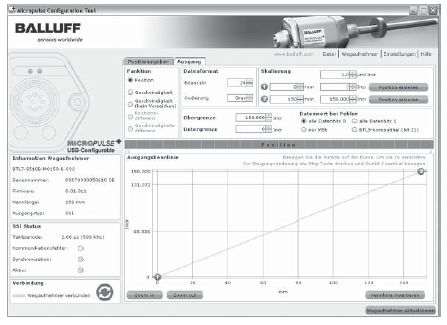

extending the full length of the mechanical stroke. A magnet ring is used as a position marker and mounted on the face of the piston. As the piston (and the position marker) move, the linear position sensor provides a continuous absolute position by way of an analog or digital signal.

extending the full length of the mechanical stroke. A magnet ring is used as a position marker and mounted on the face of the piston. As the piston (and the position marker) move, the linear position sensor provides a continuous absolute position by way of an analog or digital signal.

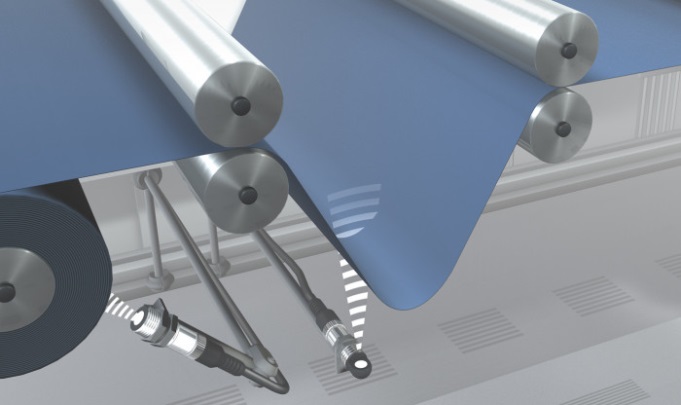

offerings as a go-to as they seem more common. Photoelectric sensors are solid performers, however they can run into limitations in certain applications. In these circumstances, considering an ultrasonic sensor could provide a solid solution.

offerings as a go-to as they seem more common. Photoelectric sensors are solid performers, however they can run into limitations in certain applications. In these circumstances, considering an ultrasonic sensor could provide a solid solution. customer needed to detect a few features on a metal angle iron. The customer was currently using a laser photoelectric sensor with analog feedback measurement, however the results were not consistent or repeatable as the laser would simply pick up every imperfection that was present on the angle iron. This is where the ultrasonic sensors came in as they provide a larger detection range matched with emitting and receiving sound energy. This provided much more stable outputs, allowing the customer to reliably detect and error proof the angle iron. With the customer switching to ultrasonic sensors in this particular application they now have better quality control and less downtime.

customer needed to detect a few features on a metal angle iron. The customer was currently using a laser photoelectric sensor with analog feedback measurement, however the results were not consistent or repeatable as the laser would simply pick up every imperfection that was present on the angle iron. This is where the ultrasonic sensors came in as they provide a larger detection range matched with emitting and receiving sound energy. This provided much more stable outputs, allowing the customer to reliably detect and error proof the angle iron. With the customer switching to ultrasonic sensors in this particular application they now have better quality control and less downtime. to think of all sensor technologies as some will provide better results than others. Ultrasonic sensors are indeed an excellent choice when applied correctly. They can measure fill levels, heights, sag, or simply monitor the presence of a target or object. They perform very well in foggy or dusty areas where some other sensor technologies fall short.

to think of all sensor technologies as some will provide better results than others. Ultrasonic sensors are indeed an excellent choice when applied correctly. They can measure fill levels, heights, sag, or simply monitor the presence of a target or object. They perform very well in foggy or dusty areas where some other sensor technologies fall short.