Guest contributor: Stefan Zimmerman

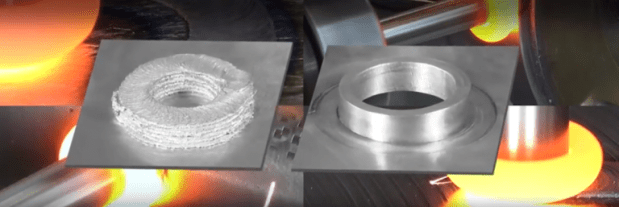

New drive concept makes hydraulics economical and intelligent

By means of variable-speed pump drives, new, patented hydraulic axes simplify the design and control of presses of any kind. They considerably reduce the power consumption as well as the required oil quantity by up to 90 percent. To this extent, the control technology of a valve control moved into the software of intelligent servo drives of a displacer control. This reduces the complexity and opens up new levels of flexibility and of condition monitoring.

Worldwide, the climate change has increasingly drastic effects on the everyday life. Thus, governments and international organizations have defined climate targets in order to limit the CO2emissions. What has already become standard in light bulbs and household devices also takes increasingly more effect in the industry. Energy-efficiency has become a decisive criterion for the machine users when it comes to the selection of machinery and systems. They expect a considerably increased output with clearly reduced current and resource consumption. Apart from that, numerous companies have already publicly obliged themselves to reduce their CO2 emissions by defined quantities. They can only achieve these targets if new machinery and systems are considerably more energy-efficient. So it is the challenge of machine manufacturers to develop new concepts.

Using the hydraulic force density as required

In large systems with very high processing forces as they are required for forming methods, the hydraulics as main drive is one of the largest power consumers. The end users have accepted this for a long time as they wanted to have the maximum force available at any time, even if the process did not permanently require it. Modern hydraulic drives distinguish themselves by the physical unique selling points such as power density and robustness; however, they clearly reduce the power consumption by controlling the displacer as required. Thanks to its hybrid concept, the new hydraulicAxis patented by Bosch Rexroth for presses of different kinds, from low to high drive power, connects the advantages of hydraulics with those of the electric drive technology. First equipment according the new concept has shown that the power consumption can be reduced by more than 30 percent. The required oil quantity of the hydraulic installation can be reduced by up to 90 percent.

Conventional hydraulic systems

For decades, conventional systems have proven of value for presses in the medium and high performance range as drive technology of choice. In this connection, these systems mostly work with a central hydraulic power unit with several variable displacement pumps. Moreover they are operated by electric motors directly connected to the mains. Apart from that, central or decentralized manifolds with on/off and proportional servo valve technology are required in order to control the cylinder(s) in rapid traverse, working or pressing mode and in the so-called return.

One disadvantage of this concept are idling losses during the standstill times. In the control of the cylinders, there are also throttle losses caused by the valve control. There is partly considerable heat introduction into the hydraulic oil, which must afterwards be compensated again by corresponding cooling.

Hydraulic axis replaces central power unit

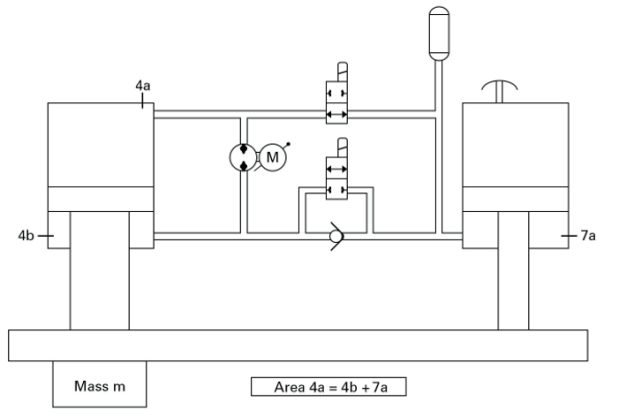

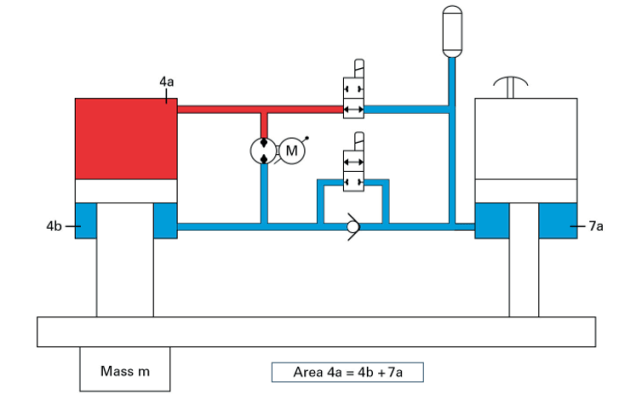

A new, patented hydraulic concept replaces the previously common central power unit with valve control by a patented hydraulic axis with speed-controlled displacer control and a closed, decentralized fluid circuit. The hydraulic axis consists of a differential cylinder with a cylinder chamber and ring chamber. The cylinder chamber is for a powerful working movement and the ring chamber for the fast rapid traverse movement. An auxiliary cylinder takes up the oscillating volume during the different movements and in this way creates a closed circuit. A central oil tank is no longer necessary and thus completely omitted.

The flow is generated by variable-speed pump drives. In order to satisfy the high precision and dynamics requirements, servomotors in combination with adjustable axial piston pumps lend themselves. Thus, all options of the 4-quadrant operation are available to the design engineers. With several cylinders, a corresponding number of Hydraulic axes is used. The synchronization control is performed by the software of the intelligent servo drives, synchronized by means of real-time communication.

Reversal of the movement by changing the direction of rotation

The area switchover for the relevant movement is effected by means of two valves. During the pressing process, the cylinder areas are large. Thus, the cylinders reach high forces at low velocity. During the return of the cylinders, however, the areas in the ring chamber are small in order to achieve the maximum rapid traverse velocity with low forces and to thus reduce the downtimes of the presses. For the reversal of the movement, the servomotors change their direction of rotation. If adjustable axial piston pumps are used, the swash plate of which can be swiveled through zero, the direction of the movement can also be changed by adjusting the swivel angle.

Energy efficiency in practice: Presses consume more than 30 percent less

The hydraulic axis works in a strictly need-oriented manner. At partial load, the servo drive controllers reduce the speeds of the pump motors to the lowest value possible. During standstill times, e.g. for cooling down the tools, the motors are standing and do not consume any energy. During that time, safety valves support the return. Depending on the cycle times, variable-speed pump drives allow for energy savings of more than 80 percent as compared to constantly driven power units without variable displacement pumps. In practice, the first presses with hydraulic axes achieved reduced consumption of 30 percent as compared to already energetically optimized, conventional hydraulic solutions.

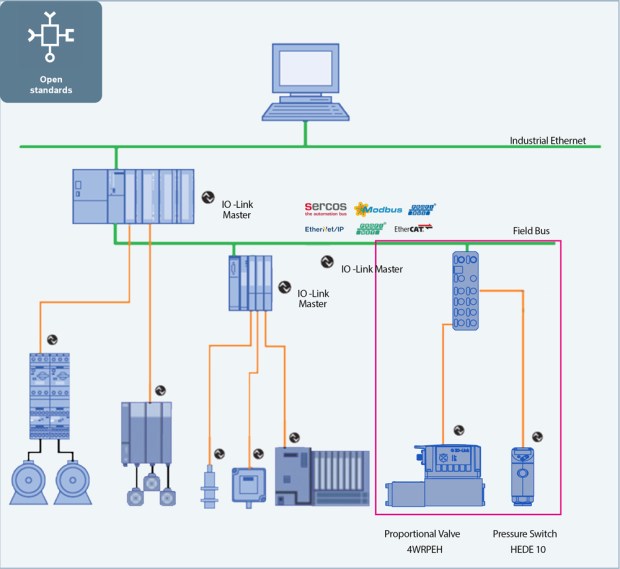

Regarding the Sytronix family, Rexroth offers more than one hundred pump drives with variable speed relating to power and function. These can be integrated into all usual automation structures thanks to multi-Ethernet interfaces.

Regarding the Sytronix family, Rexroth offers more than one hundred pump drives with variable speed relating to power and function. These can be integrated into all usual automation structures thanks to multi-Ethernet interfaces.

Exceeding the savings due to the need-based closed-loop speed control, additional functions increase the energy efficiency of the presses even further. In the lowering movement, the servomotors recuperate the braking energy and either feed it into an electric accumulator, make it available to other actuators, e.g. handling axes, via an intermediate circuit or feed it back into the mains.

Synchronization control of the hydraulic cylinders via intelligent software

The synchronization control can be effected via all common real-time protocols such as PROFINET, Ethernet IP, EtherCat or Sercos if the servo drive controllers provide corresponding multi-Ethernet interfaces. Changes in motion sequences are only transmitted via the machine control by means of software command to the intelligent drives. Mechanical adjustment works at the hydraulic axis are not necessary. So due to short changeover times, end users gain flexibility. At the same time, you can continuously document the manufacturing processes of every component by means of the servo-drive data. This satisfies the increasing demands on the traceability of products.

90 percent less hydraulic oil – central tank omitted

Due to the new concept of the hydraulic axis, the movements are primarily controlled via variable-speed pumps rather than the throttling of the flow by the valves. So considerably less heat is introduced into the hydraulic oil and only minor agitation results. Result: In the first presses with hydraulic axes, the manufacturer could reduce the oil volume from e.g. 10,000 liters to only 900 liters. This saves space for the tank and reduces the operating costs as in an oil exchange, less than ten percent of the previously used oil quantity have to be purchased and disposed of.

An additional advantage is the clearly reduced average noise emission. With variable-speed pump drives, it is up to 20 db(A) below that of constantly driven pumps. During standstill, the noise level of the hydraulics falls to zero. Due to the omitted tank and complex piping for a power distribution, resonance bodies for the structure-borne sound are omitted. With the new concept, the expenses for the noise insulation are considerably lower.

Easier hydraulic construction with quick commissioning

For manufacturers of hydraulic presses, the conversion to hydraulic axes brings about considerable savings in the design, assembly and commissioning. Tank, cooling and piping are completely or largely omitted as is the valve technology. The variance of different motion sequences is moved from the valve technology into the drive controller software. Here, Bosch Rexroth has, for example, integrated best-in-class controllers for different force/path and synchronization controls. Due to the corresponding commissioning software, the engineers don’t even need in-depth hydraulic knowledge for the initial commissioning. Software wizards propose suitable parameters. This considerably shortens the commissioning phases of a hydraulic press.

Condition monitoring increases the availability

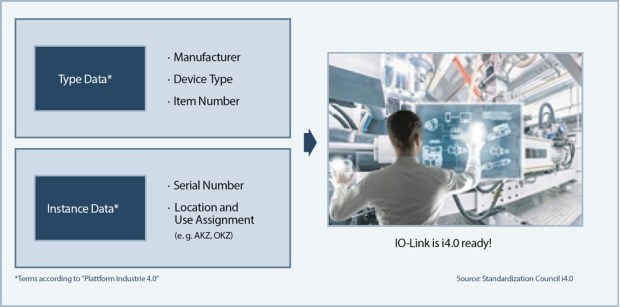

The data that is gathered by the intelligent servo drives anyway and that can be amended by more sensors is particularly interesting for end users. It forms the basis for condition monitoring strategies increasing the availability. Based on the analysis of the data, the corresponding software identifies wear and errors before they will lead to standstills. So machine downtimes are replaced by scheduled maintenance measures.

Find out more about self-contained hydraulic actuators here.

CMA/Flodyne/Hydradyne is an authorized Bosch Rexroth distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

CMA/Flodyne/Hydradyne is an authorized Bosch Rexroth distributor in Illinois, Wisconsin, Iowa and Northern Indiana.

In addition to distribution, we design and fabricate complete engineered systems, including hydraulic power units, electrical control panels, pneumatic panels & aluminum framing. Our advanced components and system solutions are found in a wide variety of industrial applications such as wind energy, solar energy, process control and more.

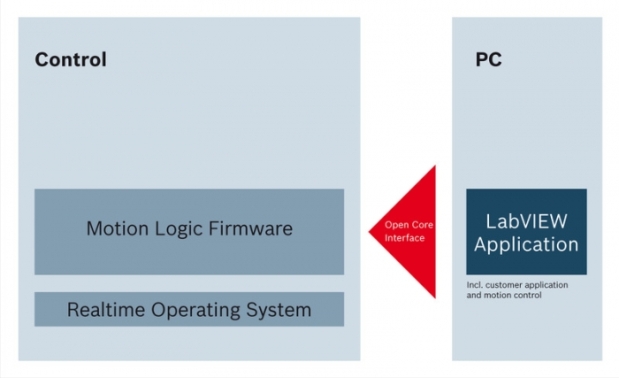

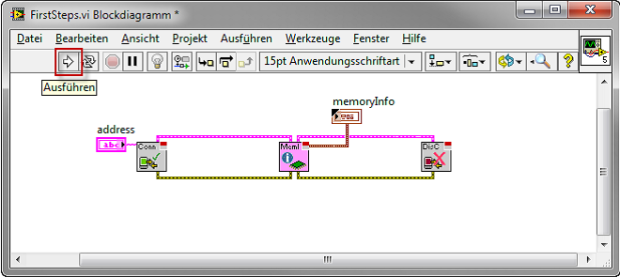

Simple block diagram: In this example, the logically linked Virtual Instruments read a value from the control unit.

Simple block diagram: In this example, the logically linked Virtual Instruments read a value from the control unit. Quick access to the desired operating interfaces: The SDK for LabVIEW comes with lots of example projects in which the HMI can be quickly and easily adjusted.

Quick access to the desired operating interfaces: The SDK for LabVIEW comes with lots of example projects in which the HMI can be quickly and easily adjusted.

The assembly line at the Hannover Messe.

The assembly line at the Hannover Messe.